Global leaders in business and politics came together at the World Economic Forum annual meeting in Davos, Switzerland, in January 2017 to set the world’s industrial agendas for the year ahead. Among the topics under discussion was how best to prepare for the impact of the Fourth Industrial Revolution which, according to Professor Klaus Schwab, founder and executive chairman of the World Economic Forum, is fundamentally changing the way we live, work and relate to one another.

Transforming industry

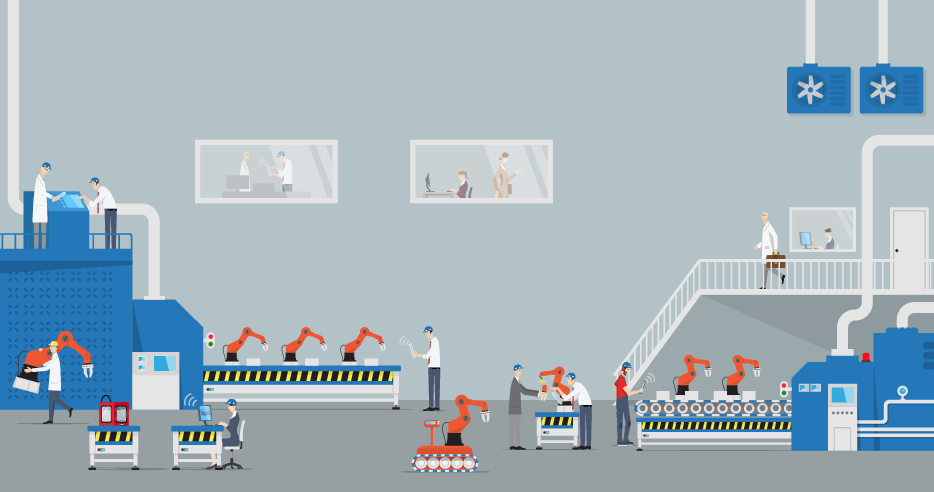

Recent uses of digital manufacturing demonstrate how collaboration between industry and manufacturing can lead to significant advancements in those industries.

For example, the healthcare sector has utilised 3D printing techniques to support innovation in the medical industry, such as 3D printed limbs and skin. And CNC machining, which uses automated software to control high-speed milling and turning tools, is employed by the University of Houston in the creation of custom-machined aluminium-joint housings for a powered exoskeleton, which forms a key part of a new robotics system aimed at helping paraplegics to walk again.

In the Energy sector, CNC machined parts are a key feature of an innovative, highly efficient solar panel system innovatively designed by Texas-based Skyven Technologies to both generate electricity and heat water.

And this is just one example of how digital manufacturing technologies can be applied to support companies in becoming more sustainable, particularly when they’re increasingly required to meet emission and efficiency targets.

Examples of best practice

The almost infinite variety of objects—and iterations of objects—that 3D printing can produce, now reduces the need for maintaining a lengthy product inventory. This is because complex parts are built using the exact amount of material needed, resulting in minimal excess and waste. This streamlines the production of prototypes and parts, leading to an efficient global supply chain, and ultimately helps to promote a less wasteful and more sustainable way of working.

Industries such as automotive and aerospace have embraced digital manufacturing techniques as ‘best practice’ to attain positive, sustainable results in their production cycle.

In light of strict EU regulations around reducing carbon emissions, manufacturers in the automotive industry are seeking to increase the efficiency of vehicles by reducing their weight – often by just a fraction of an ounce. To do so, they embrace the latest methods of design and manufacture to develop new materials, then test the impact on weight reduction through a process of iterative prototypes.

Advances in manufacturing techniques are also helping aeronautical companies in their quest to reduce weight and emissions, increase cargo capacity, and improve the overall passenger experience.

As aircraft and their component parts become smaller, more lightweight and efficient, so the geometry of these parts becomes increasingly complex. By turning to 3D printing, the complexity can be reduced, especially in situations where multiple parts must be printed simultaneously and require advanced dimensional tolerances.

Opportunities and challenges

A change of mind-set is required for businesses to make the most of the opportunities presented by the Fourth Industrial Revolution.

Technology is evolving and developing at a rapid pace, changing the way that individuals and businesses do business with each other. Whether to save costs, improve efficiency, or meet industry regulations, it’s important that businesses co-operate, collaborate and share the benefits of digital manufacturing technologies, in order to remain competitive.

Stephen Dyson is the head of industry 4.0 at Proto Labs.