3D printing is leading many to wonder if the technology is more than just a hype.

The technology has already existed since 1983, but in the last year it really caught people’s attention with guns being made, baby’s lives being saved and brands like Nike, McDonalds and HP announcing market entry.

Furthermore, on Kickstarter more than 110 3D printing projects were launched – illustrating the appeal with smaller companies. So is 3D printing just a hype, or are there new business opportunities in 2014?

I believe that businesses can extract real value from 3D printing, giving them the opportunity to manufacture their products on-demand, instead of having to build stock of thousands of units. Centralised mass-production leads to inefficient distribution and waste.

Your eyewear was probably produced in China, then shipped to a remote distribution centre somewhere across the world and finally shipped to end up at your local store. Unsold glasses are most likely thrown away. Experts estimate that 30 per cent of all product stock goes unsold, which is unsustainable and means significant losses for businesses.

The number of products that can be produced competitively with 3D printing is still small, but also growing rapidly thanks to hardware improvements. Tens of millions of products, such as braces and hearing-aid casings, have been 3D printed this year.

Cities with at least one 3D printing location on 3D Hubs. London has 40 printing locations

The great thing about 3D printing is that it can largely decrease the threshold for people to start a consumer product business. You don’t need to put large investments into moulds, assembly lines and stock. All you need is a 3D design and access to a 3D printer.

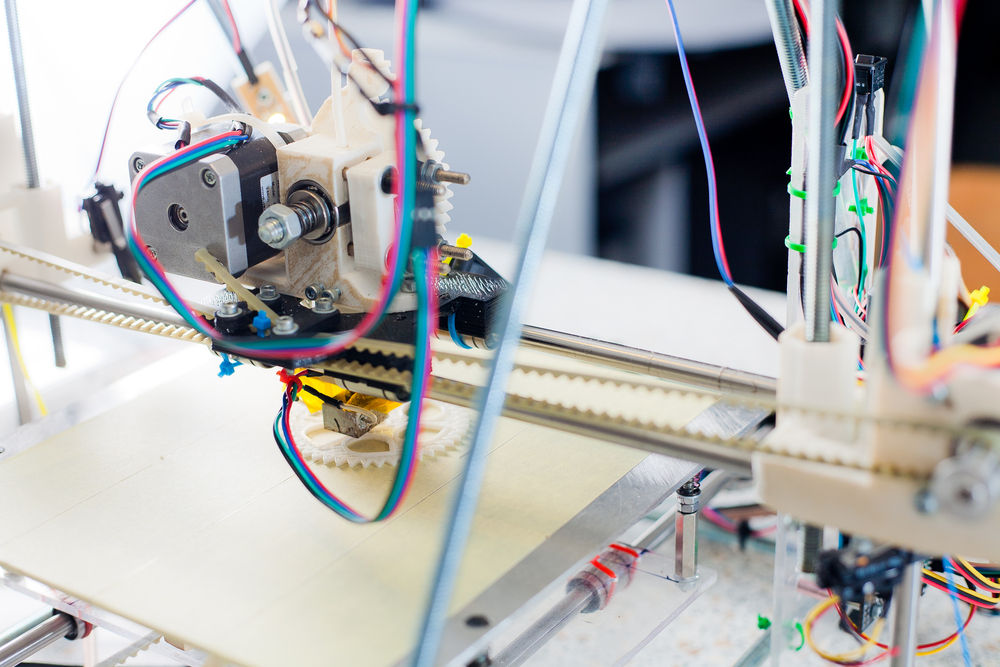

These machines range from £1,000 to £1 million depending on the quality and maximum build size of designs required. People who don’t want to invest in their own machine can also tap into existing platforms like 3D Hubs (which I co-founded), a global production network of 2,200 3D printers.

Product collection can then be manufactured close to the end-user, minimising shipping costs and always providing access to the most up-to-date 3D printers and materials.

3D printing is expected to do for consumer product companies what cloud servers did for internet companies – giving everyone the opportunity to start a business, hopefully resulting in the disruptive startups similar to those that came with the rise of the internet.

Freshfiber is an example of a company that benefited from the new opportunities created by 3D Printing. The company was able to build a popular line of iPhone cases, in just a couple of months, that can now be found in Apple stores across the globe. Just two years after launch they were acquired by NYSE-listed 3D Systems.

Start-ups are finally getting a chance to compete with large consumer brands and it will be interesting to see how fast these brands can adapt.

3D printed shoes by Nike (left) and Recreus (right)

A company like Nike already produces custom shoe soles for professional athletes on large industrial 3D printers. But at the same time there is Ignacio from Spain which designs the Recreus shoe that can be made in one go on a £2,000 3D printer sitting on your desktop. By making his design freely downloadable on Thingiverse, an online repository of over 100,000 3D printable designs, the founder provides a glimpse of the supply chain disruption that is about to take place.